Metsä Group is building the world´s first next-generation bioproduct mill

Case - Published 20.6.2016

Metsä Fibre, which is part of Metsä Group, is building a new bioproduct mill in Äänekoski in Central Finland. An energy-efficient, next-generation pulp mill will serve as the core of the bioproduct mill. Its annual pulp production capacity is 1.3 million tonnes. In addition to high-quality pulp, it will produce a broad range of other bioproducts. The mill is designed to allow for a broad, diverse range of products manufactured by a unique bioeconomy ecosystem of companies.

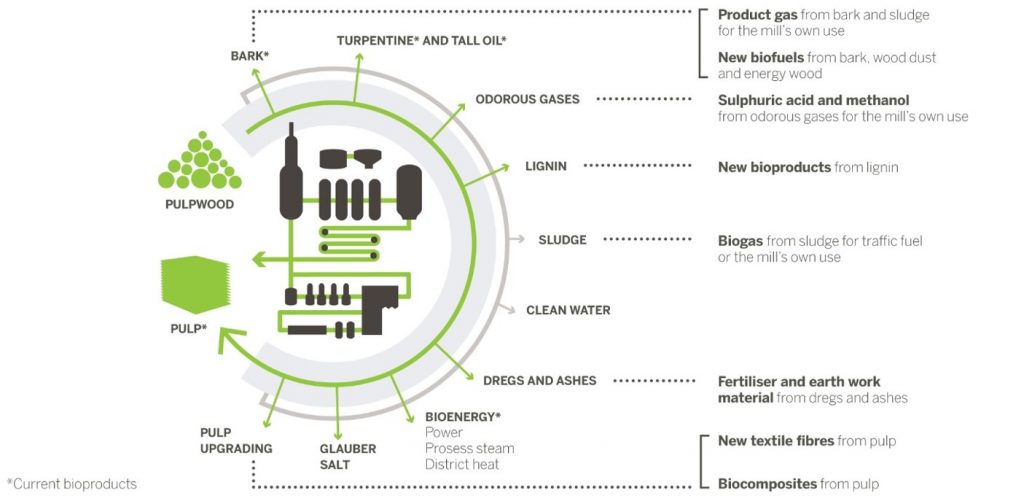

The Metsä Group’s new bioproduct mill will use 100 per cent of the raw materials and side streams for manufacturing and energy production, and it will not use any fossil fuels whatsoever. All of the energy needed by the mill will be produced from wood. The bioproduct mill will also produce a broad variety of bioproducts and its electricity self-sufficiency will be 240 per cent.

The bioproduct mill is the largest investment in the history of the Finnish forest industry. Once the new mill is fully operational, its employment effect throughout the value chain in Finland will be 2,500 jobs, including 1,500 new jobs. The most significant employment effects are expected to be in the forest industry and transport.

The mill is constructed in the area of the present Metsä Fibre pulp mill in Äänekoski in Central Finland. The new mill will replace part of the existing mill and serve the local forest industry. The present Metsä Fibre pulp mill will be in operation until the new bioproduct mill starts operating in the third quarter of 2017.

The mill will use side streams to produce pulp, energy and bioproducts

In recent years, the demand for softwood pulp has grown around the world, particularly in China. The bioproduct mill will produce softwood and birch pulp as raw material for paper, board, tissue and special products. The mill will produce 1.3 million tonnes of pulp per year which means the pulp production in Äänekoski will almost triple.

Tall oil is used to produce glue, paints, ink and biofuels bitumen emulsions, plant protection products and drilling oils, among other products. Turpentine is used in the production of odorants and paints, for example. Pulp production also creates bioenergy products, such as bioelectricity, process steam, district heat and bark-based solid fuel. District heat, for example,, can be used by the town of Äänekoski.

The mill will produce 2.4 times the energy it consumes, and increase the share of renewable energy in Finland by more than two percentage points. The main fuel for the limekiln at the bioproduct mill will be gaseous biofuel made from bark.

In the early phase of production approximately 20 per cent of the net sales volume will be based on the processed side stream products and the share will increase gradually. Other potential bioproducts include sulphuric acid, methanol, biocomposites, fertilisers and biogas. Also, the manufacturing of textile fibres, and lignin products is being evaluated. Metsä Group is studying several processes and product paths and will implement them gradually. It will take some time to reach the goals once the mill is in operation.

Raw material from sustainably managed forests

As the bioproduct mill starts production it will have a significant influence on the use of wood in the whole of Finland. The mill will use 4.5 million cubic metres of softwood and 2 million cubic metres of birch per year. It will increase the annual consumption of pulpwood in Finland by around 4 million cubic metres (around 10 per cent). Most of the increase will consist of softwood pulpwood. The pulpwood will mainly be purchased in Finland. The mill’s location is ideal in terms of availability of raw materials, and the necessary logistics networks are already in place.

Softwood is mainly collected in connection to forest thinning. Sustainably managed forests serve as carbon sinks that help to mitigate climate change. The intention is to purchase most of the wood used by the mill in Finland. 90 per cent of the wood used will be certified wood.

Did you know that the amount of Finnish wood the mill uses per day will grow back in 40 minutes?

The bioproduct mill is a significant step for the Finnish bioeconomy

Metsä Group’s bioproduct mill has a significant effect on the Finnish economy through employment and economic growth. The bioproduct mill will diversify the structure of the Finnish forest economy and bioeconomy and expand their product selection through high value added products. The bioproduct mill is the largest investment in the history of the Finnish forest industry. When completed, it is expected to have an annual impact of more than EUR 0.5 billion on Finland’s income. The annual increase in the value of exports will be EUR 0.5 billion.

Additional information Anna-Liisa Pennanen, Metsä Group, anna-liisa.pennanen@metsagroup.com

Published: June 20, 2016