Meet the Scientists of the Future Bioeconomy part 5: Engineering fungal mycelium to produce leather without cows

Blog - Published 28.6.2021

The fashion industry has a huge carbon footprint that is growing rapidly. In the NewLeather project at VTT, senior scientist Géza Szilvay and his team are tackling one part of that carbon footprint by developing a fungus-based leather. They are using biotechnology to re-engineer mycelium to produce a leather-like material that has many advantages over animal-based leather.

Environmental challenges such as climate change and biodiversity loss are forcing us to review traditional means of production, consumption and even thinking. Although we are slowly shifting our fossil-based economy to a more sustainable circular economy, carbon emissions must be reduced rapidly if we want to change in time. One sector that must make big changes is the fashion industry. In fact, it is responsible for 10 % of global carbon emissions, which is more than all international flights and maritime shipping combined. One of the biggest problems within the fashion industry is leather production. The environmental impact of leather is mainly due to cattle farming, and its carbon footprint is estimated to be as high as 130 million tons annually. This is equivalent to the co2 emissions of 30 million of passenger vehicles.

This problem is under the microscope at VTT, where scientists have developed a leather-like material made by fungi, thereby creating an environmentally benign alternative to traditional animal-based leather. Replacing leather would result in less cattle farming which in turn would lower carbon emissions and free up more agricultural land for food production. Furthermore, the use of chemicals in the production process would be dramatically reduced. This is important for us all. For example, the chromium emissions from tanning leather have been proven harmful for both humans and the environment.

Redesigning the mycelium

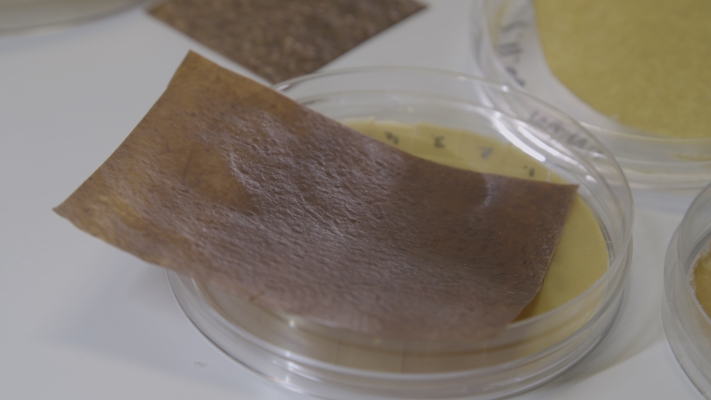

To produce the faux-leather material, the scientists use only the fungal mycelium, also known as the root structure of the mushroom. This microbe naturally grows a filamentous structure. In the future, synthetic biology will allow scientists to design the final material from the cellular level, which will enable them to achieve specific, desirable properties. For instance, they can introduce new proteins or change the metabolic pathways to change the structure of the mycelium. “So, we can start to bio-engineer mycelium and play with the strength, tear resistance, abrasion resistance. Try to bring in new functionality into the material by engineering methods,” explains Géza Szilvay.

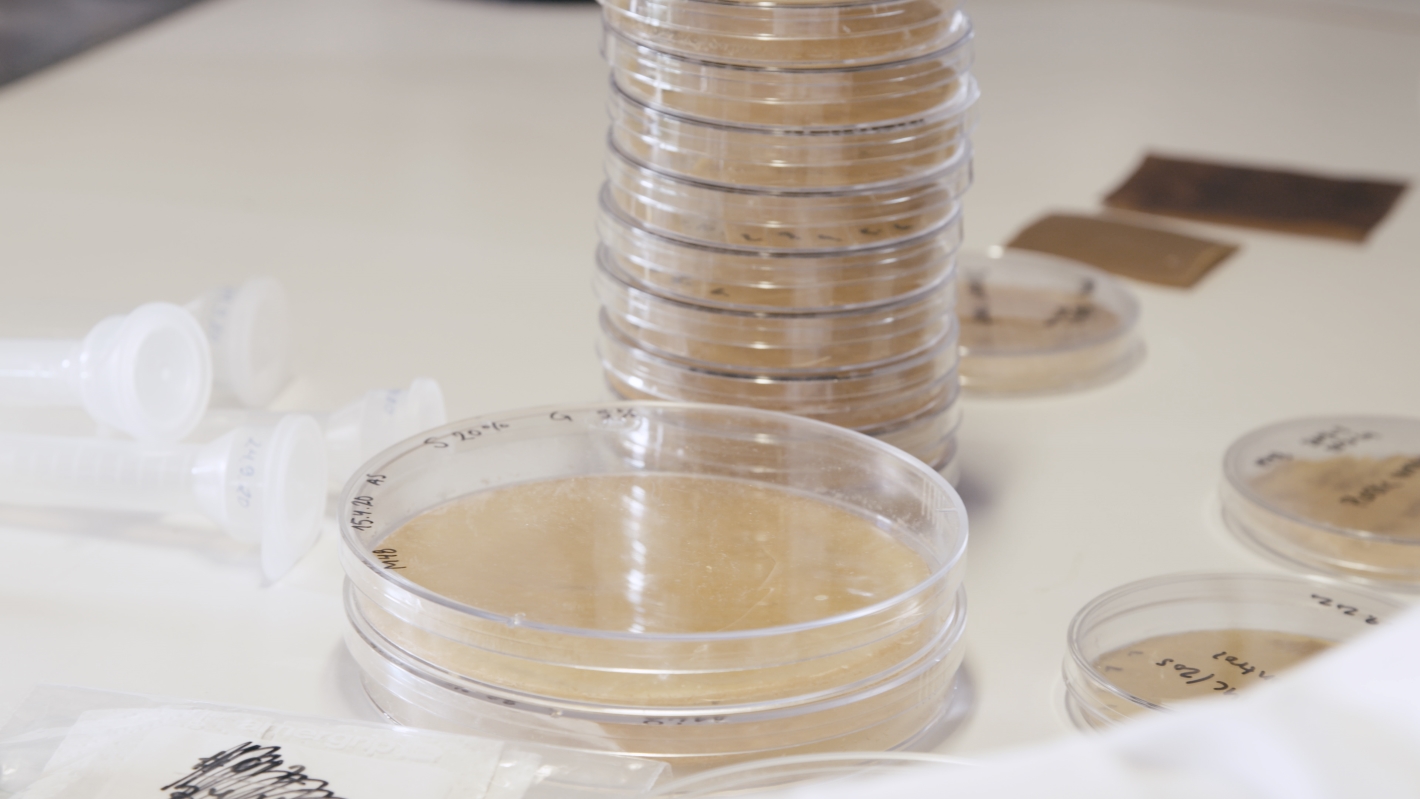

Genetic engineering is a tool that enables researchers to control the microstructure of the mycelium. They can, for example, make the filaments stronger, improve their interaction with other components or even make the final material more durable. After careful engineering, the mycelium is grown in conditions optimized for comfort and growth. Finally, the harvested mycelium is treated and processed into a nonwoven structure resembling a sheet.

No need for fields

One promising aspect of fungi-based materials is that the fungi can be fed with organic side streams, such as food or agricultural waste. And there are other advantages as well. “Because we do not need fields, we can grow the material in bioreactors with barely any land area. We don’t produce so much carbon-dioxide as is done with cows, for example, and the end-product is biodegradable,” says Szilvay. Bio-based leather alternatives are being developed by scientists across the world, and although some items have already entered the market, there are still unsolved challenges to bringing these novel materials to industrial-scale production. This is where biotechnology has an advantage because it is more easily scalable than many other production processes. However, the NewLeather fungus-based leather production process still needs some fine tuning before entering the market. Szilvay explains: “We want to make the efficiency of growing and making the processing into fabric, we want to make this much more efficient. And this would enable these materials hopefully to get to the market much faster and cheaper also, so that prices should not be an obstacle in taking this up into the market.”

Reshaping the future

The multidisciplinary NewLeather project was part of the VTT’s iBEX programme which funds solution-oriented research that aims to develop world-changing innovations. The NewLeather project was a collaboration that brought together scientists and designers with the goal of developing a new way to produce leather with biotechnology. One of the designers in the project is Manuel Arias Barrantes who thinks designers will be working more and more in labs together with scientists. “As designers, we are used to thinking of the end-user and their needs, so by working closely with the scientists we are able to produce science that also has value to the end-user. We are able to envision future applications and create prototypes to make scientific research tangible to people”.

The demand for sustainable materials is enormous, and the research and development of biomaterials is brimming with new innovations. Synthetic biology is offering new paths to sustainable production of materials, chemicals, medicines and even food. Sustainable production is a cornerstone of the UN sustainable development goals, which promote innovation as well as responsible production and consumption. As the biotechnology sector witnesses a rapid growth in investments, the value of the global market in synthetic biology is estimated to be several billions with a growth forecast of 25% annually. It is intriguing to think that some of these innovations are being created in microscopically small environments. Harnessing the potential power of the smallest microbes and fungi just might have a big role in revolutionising the materials economy.

Text has been corrected on 2.8.2021. The emissions of leather production are 130 million tons.

Agenda2030

The project supports UN sustainable development goals as it promotes sustainable innovations, production and consumption (9., 12.).

Meet the Scientists of the Future Bioeconomy

The future of our bioeconomy is in the making. In this series we present the scientists and science behind the groundbreaking discoveries that will have a great impact on a sustainable circular bio economy. How will synthetic biology, advanced biomaterials research and new applications using lignocellulosic fractions contribute to a more sustainable future? In this series you will be invited behind the scenes to meet some of our most brilliant young scientists working on solving some of the most pressing challenges of our time.